INFICON Aquires FabTime

We are proud to announce that INFICON has acquired FabTime. INFICON provides software, services, hardware, and consulting to the semiconductor industry, supporting factory scheduling, operations management, and process control with sensor integration. FabTime's flexible reporting has been instrumental in empowering fabs with clear and immediate visibility into factory performance, leading to marked improvements in cycle time, capacity, productivity, and profitability. FabTime will augment the skills and capabilities of INFICON and accelerate the realization of autonomous semiconductor factories.

Press Release"What if there was a software that allowed everyone to not only access the data, but chart and graph the data in whatever format suited the task at hand? That tool, that software, is FabTime."

~Jimmie Darrington, Microchip Technologies

THE data you need When you need it.

Optimize your factory performance with on-demand data-driven insights.

Transparent Operations

Gain comprehensive visibility into your data with holistic and granular views of your operations

Save Time and Money

Costs a fraction of maintaining internal reporting systems and offers factory management and IT teams more time to focus on core tasks

Instant Insights

With a couple of clicks, fab management can view real-time graphics of their factory data

Elevated Profits

Experience increased profits through reduced lost capacity, shortened cycle times, and optimized resource allocation

One Source of Truth

Rely on one accurate data source for reporting, ensuring sustainable data governance

User-Friendly Interface

Created for all levels of factory management to interact with their data without programmer knowledge

Factory Insight Engine

Designed to equip those overseeing manufacturing operations with out-of-the-box insights

Designed for All Factory Levels

User-friendly Interface

From operators to senior managers, factory personnel can obtain relevant data through our intuitive interface. Whether a production lead wants to see metrics for moves or a fab manager needs KPI reports, these FabTime charts are designed to accommodate these varied needs.

Real-Time Dashboards

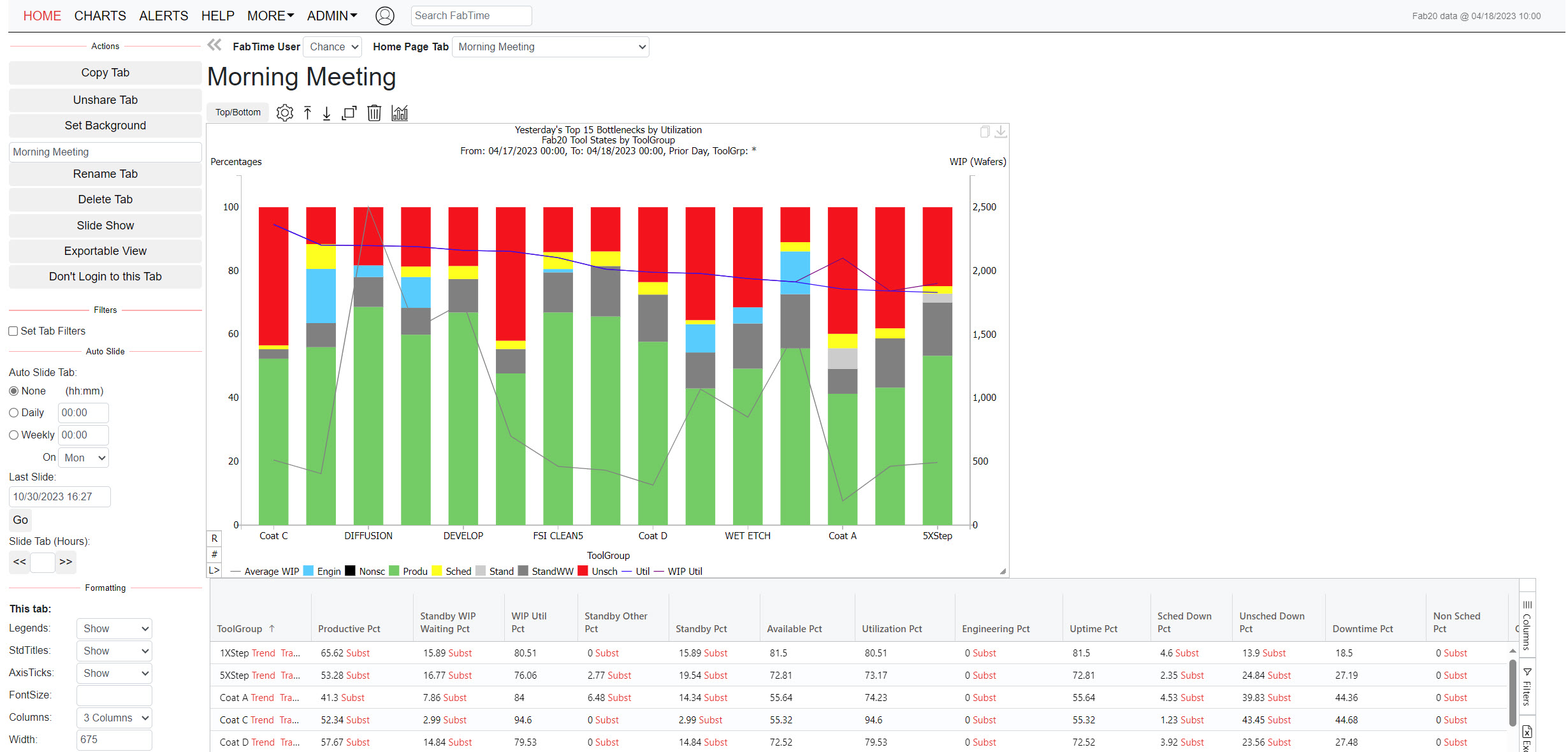

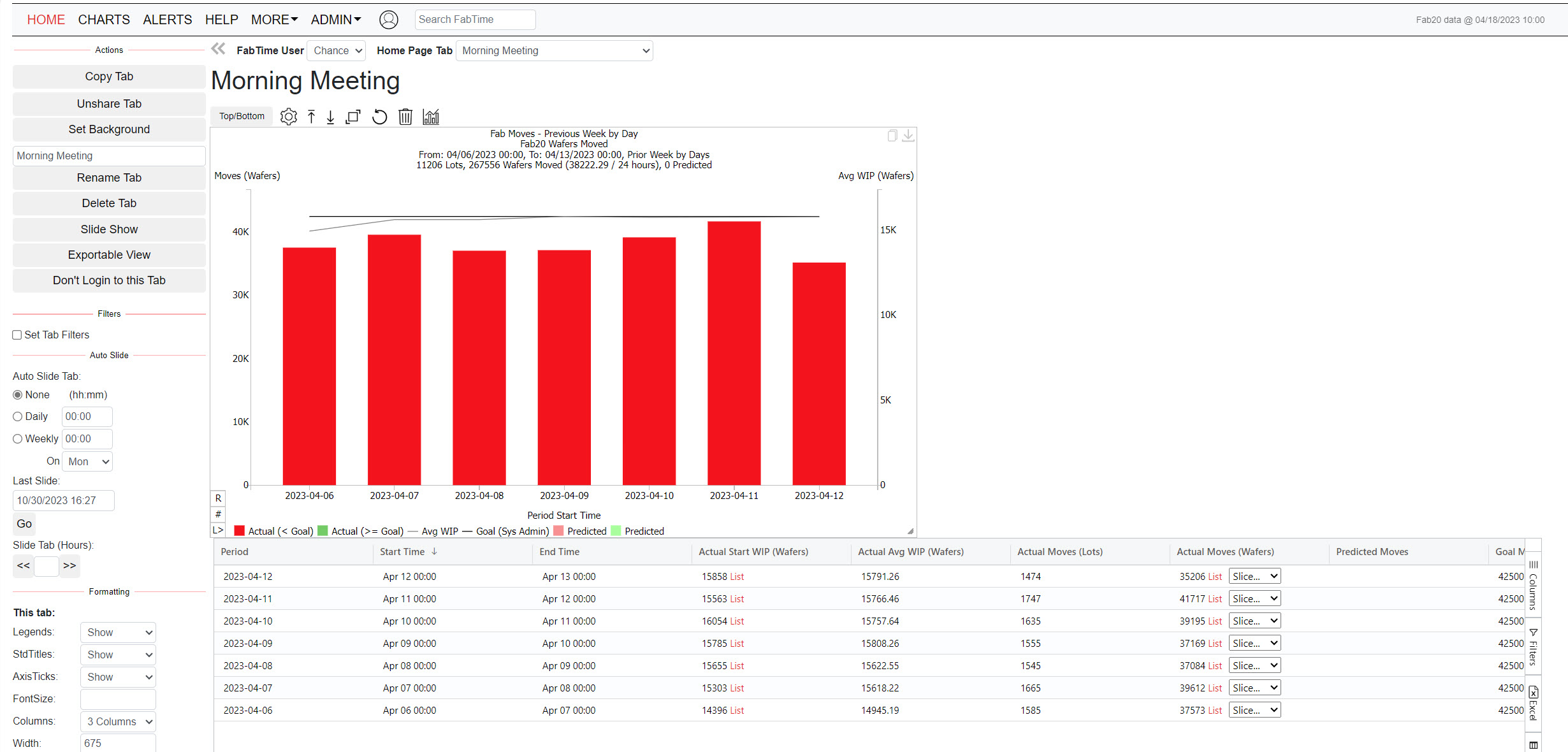

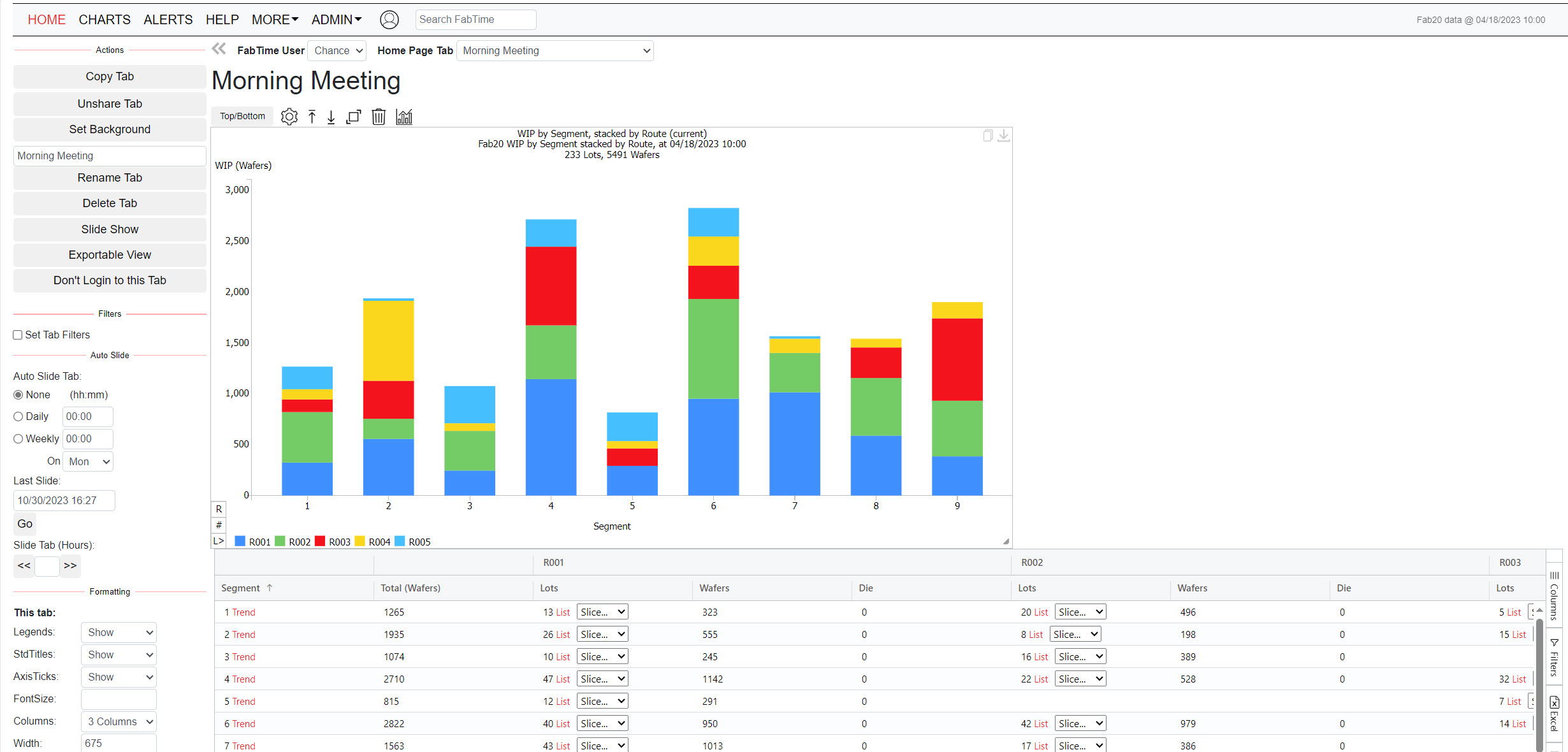

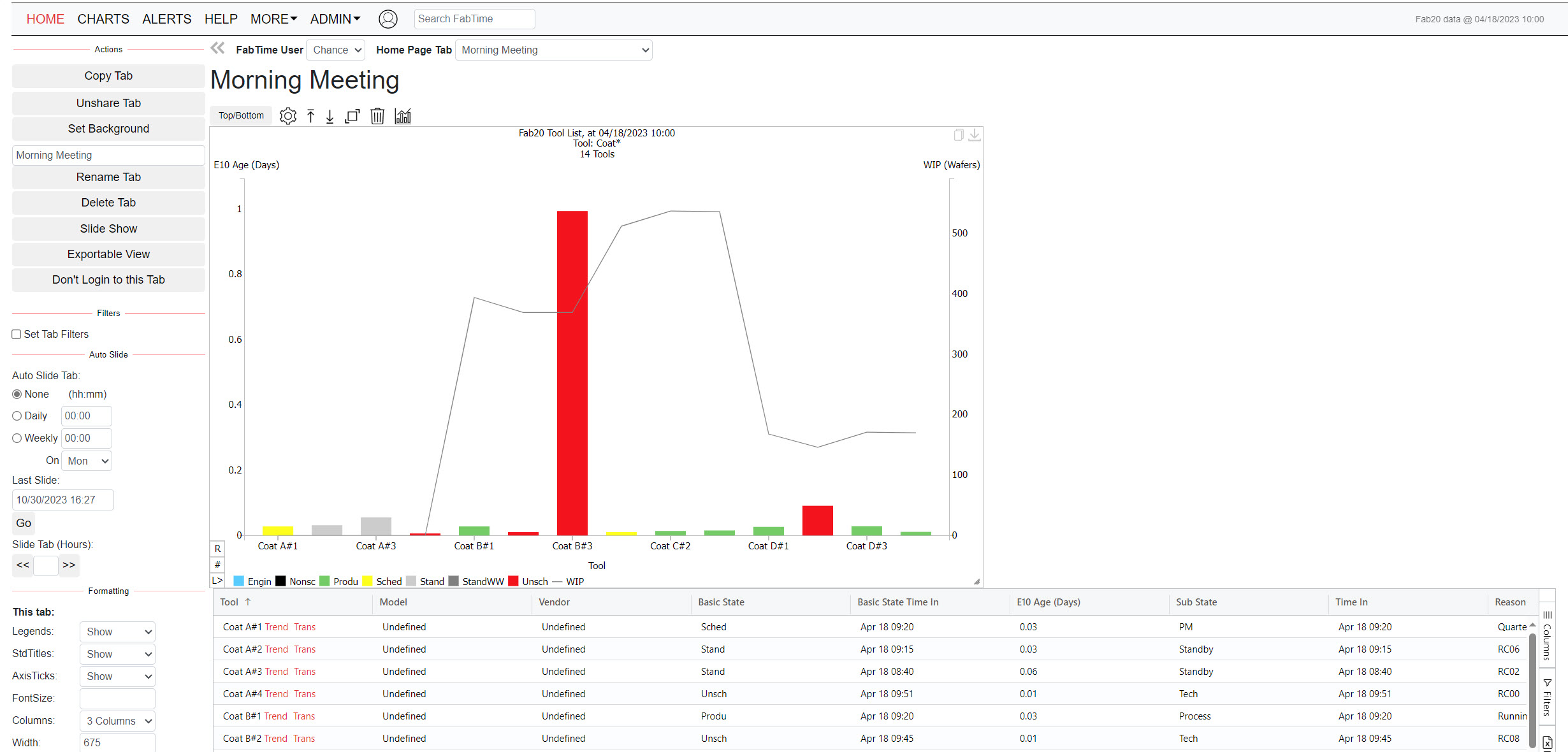

Immediate Clarity of Your Factory's Conditions

When you sign into the FabTime interface, the first thing you see is a home dashboard displaying real-time charts of your factory's performance. The adaptability of these dashboards allow you to tailor your view, from a concise overview using sparkline charts to detailed transactional-level data.

Ready-to-use Factory Charts

Out-of-the-Box Insights

Sidestep creating charts from scratch with 165 fab-specific charts at your disposal. These are designed in line with best practices for data governance and adhere to SEMI standards E10 and E79. In a couple of clicks, you can configure charts to your specifications to obtain the information you need.

Copyright ©1999-2024 FabTime Inc.