Dispatch Configuration

Configuration projects are offered as an additional fee, on top of your FabTime® subscription, and include:

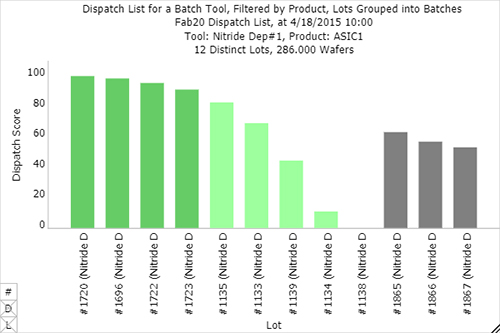

- Dispatch rule and factor configuration

- Training

- Dispatch list feed to the MES (if applicable)

Dispatch Factors

- Batch code at the current tool

- Lot priority

- Downstream tool priority

- Current tool FIFO

- Current tool idle time

- Downstream batch efficiency

- Critical ratio

- Earliest-due-date

- Current step processing time

- Remaining processing time

- Current step qualified tool count

- Up to twenty other site-specific factors